Digital Twin Testing

Virtual Relay Testing with PS Simul

Digital Twin technology is transforming the way electrical systems are tested and validated. By creating exact virtual replicas of physical devices, this innovation allows simulation, analysis, and prediction of equipment behavior without the need for physical hardware. This concept has been widely adopted across industries, bringing benefits such as cost reduction, process optimization, and increased operational reliability.

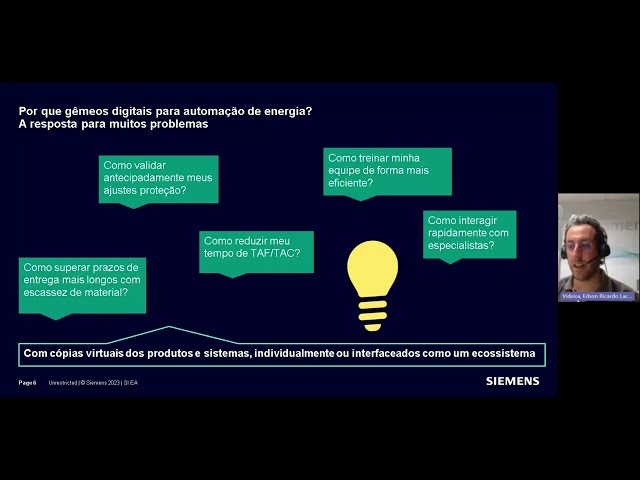

In the electrical sector, this revolution reaches protection relays (IEDs), enabling testing and simulations to be carried out in a fully digital environment. This means that it is possible to test, validate, and optimize an IED configuration without needing physical equipment or test sets, providing greater agility, safety, and efficiency in protection and automation projects.

What is a Virtual IED?

A Virtual IED is a digital version of a real protection relay, accurately replicating its functionalities, algorithms, and communication interfaces. This enables advanced testing, ensuring that the device operates correctly even before being physically installed.

With this approach, protection and automation engineers can validate logic schemes, test fault scenarios, and simulate real events without relying on physical equipment, making the process faster and more efficient.

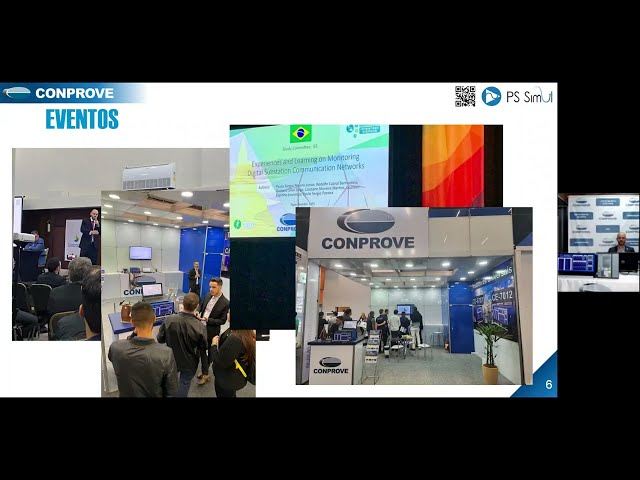

Benefits of a Virtual IED

With the Virtual IED, your process gains efficiency at various stages:

- Implementation: optimized planning and adjustments.

- Commissioning: faster FAT and SAT testing.

- Operation: remote control and monitoring.

- Training: remote and flexible access to the virtual device.

- Maintenance & Services: advanced fault analysis, enabling exact reproduction of events and operating conditions.

Video

Activate the English subtitle

Why adopt virtual testing?

Transitioning from physical to digital testing brings strategic benefits for companies and professionals in the sector:

- Shorter timelines – Faster energization of new systems.

- Lower operational costs (OPEX) – Reduced interruptions increase system availability.

- Less investment in hardware (CAPEX) – Reduces the need for test sets and physical devices.

- Remote and agile support – Reproduce failures and solve problems from anywhere.

- Dynamic and continuous training – Realistic experiences without physical constraints.

PS Simul – The Future of Testing with Digital Twins

CONPROVE, a reference in electrical testing solutions, has incorporated this innovative technology into PS Simul (Power System Simulator), a robust and complete software that allows modeling and simulation of complex electrical systems.

PS Simul was developed to meet the needs of engineers and specialists in the electrical field, providing an advanced environment for power system analysis and testing.

Main features of PS Simul:

- Modeling of complex electrical systems with transient simulations.

- Complete library with 400+ exclusive components for advanced analysis.

- Intuitive interface for waveform visualization and result analysis.

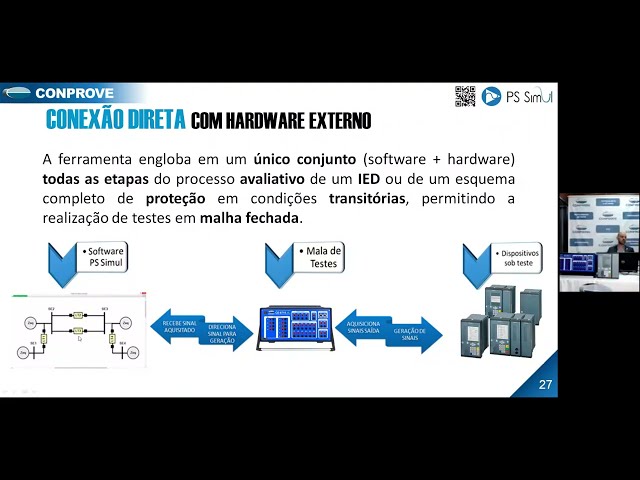

- Compatibility with test sets and Siemens Siprotec Virtual IEDs.

- Digital feedback processes enabling recursive and dynamic tests.

Iterative Testing

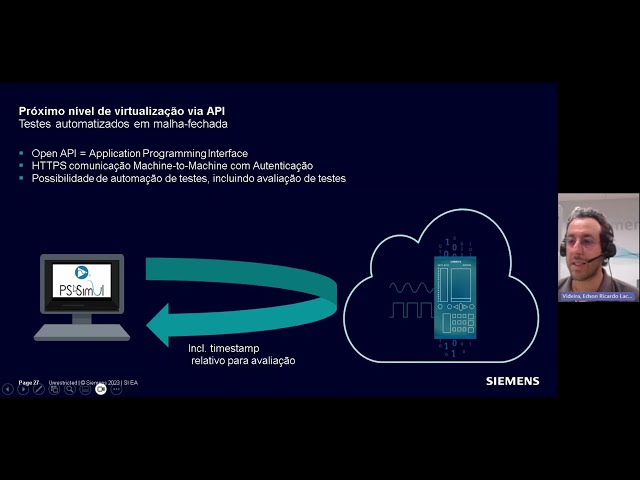

One of PS Simul’s great innovations is the ability to use digital inputs to feed back the simulation through an iterative, recursive process. This means the system can interact with generated signals, applying logic to open and close circuit breakers or any other point in the circuit involving digital logic.

This signal generation and acquisition process occurs through automatic stage overlapping with feedback, creating a closed-loop system in steps, allowing a much more realistic evaluation of protection system behavior.

Comparação de Performance entre IEDs DigitalTwin e Dispositivos Físicos através de Testes em Malha Fechada