Protection Relay Testing: Reliability and Safety for the Power System

Protection relays play an indispensable role in the operational safety of power systems, being responsible for detecting faults and commanding circuit breaker operations to isolate affected sections, ensuring continuity and integrity of the electrical grid. To ensure reliable performance, relays must undergo regular and rigorous testing, confirming that they are properly configured and operating correctly.

Importance of Testing Protection Relays

Testing protection relays is a mandatory and strategic step in commissioning, preventive and corrective maintenance, periodic inspections, and Factory Acceptance Tests (FAT) and Site Acceptance Tests (SAT). These tests verify relay performance under simulated fault conditions, ensuring that protection functions respond accurately and within the proper time.

Conprove Solutions for Relay Testing

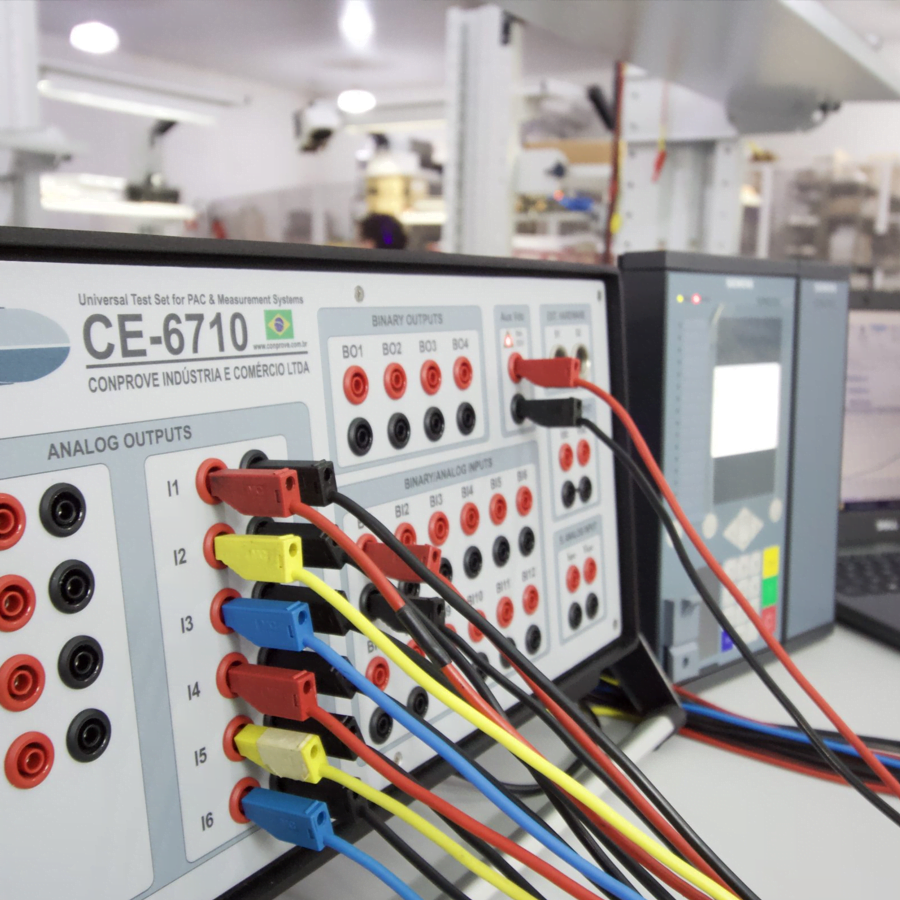

Conprove is a national reference in technology for testing protection, automation, and measurement equipment. To meet the sector’s needs with efficiency and innovation, we have developed a complete line of universal testers, versatile and robust, capable of testing any type of relay — from the simplest to multifunctional and digital IEDs.

Our relay testing equipment is compatible with major industry standards and allows:

Precise generation of current and voltage signals;

Execution of automated test sequences;

Dynamic and real-time simulations;

Evaluation of operating times;

Dual and simultaneous injection testing;

Comprehensive analysis with automatic technical reports.

Closed-Loop Iterative Testing

Conprove offers an innovative methodology based on closed-loop iterative testing, validating the full logic of relay operation in interaction with other devices, such as breakers and IEDs.

This approach checks:

Consistency between relay behavior and programming logic;

Total operating time compared to breaker opening/closing logic;

System performance in realistic conditions, considering communication and device response times.

This methodology ensures a high level of reliability, detecting hidden protection logic failures that conventional tests may miss.

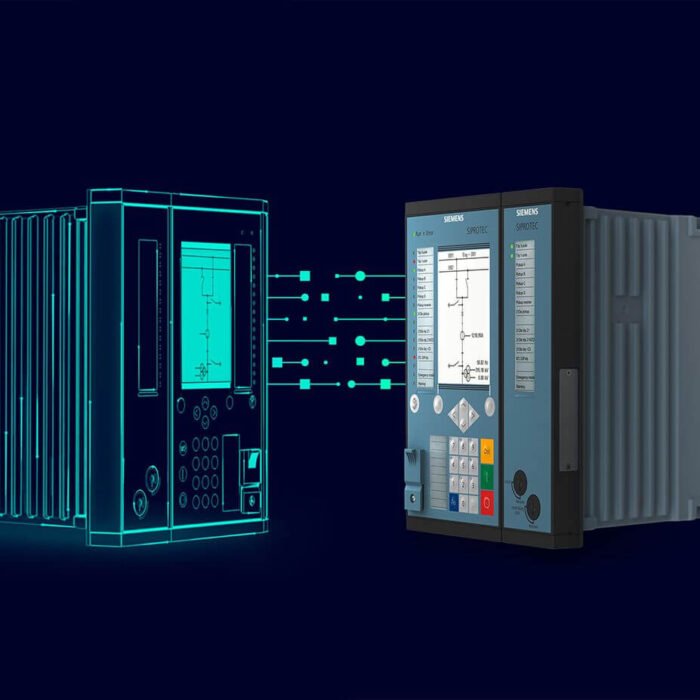

Testing with Digital Twin

Digital Twin technology is revolutionizing how electrical systems are tested and validated. By creating exact virtual replicas of physical devices, it enables simulation, analysis, and prediction of equipment behavior without physical hardware.

In the electrical sector, this innovation allows protection relays (IEDs) to be tested and validated in a fully digital environment, ensuring agility, safety, and efficiency.

Conprove has incorporated this technology into its PS Simul software, a powerful tool for modeling and simulating complex power systems.

Key features of PS Simul:

Modeling of complex electrical systems with transient simulation;

Library with 400+ exclusive components;

Intuitive interface for waveform visualization and analysis;

Compatibility with test sets and Siemens Siprotec Virtual IEDs;

Digital feedback processes for recursive and dynamic testing.

Real-Time Simulator Amplifier

Conprove also offers the CE-LVA1 Low-Level Analog Adapter, allowing its test sets (CE-6707, CE-6710, CE-7012) to act as signal amplifiers for real-time simulators such as RTDS®, OPAL-RT®, or Typhoon HIL®.

This enables high-fidelity closed-loop tests, amplifying low-level simulator signals for direct relay testing.

Applications and Benefits

Conprove relay testing solutions are applied in:

New system commissioning;

FAT/SAT tests;

Preventive and corrective maintenance;

Regulatory inspections;

Modernization and retrofit projects.

Main benefits:

Reduced testing time with automated solutions;

Precise diagnostics with graphs, measurements, and reports;

Increased plant operational safety;

Compliance with IEC 61850, IEEE C37, and other standards.

Discover Conprove’s Solutions

From substations to industrial plants, generation, transmission, and distribution systems, Conprove provides the best technological and methodological resources for protection relay testing — developed in Brazil, with specialized technical support, full training, and continuous innovation.